Micronizer Line — Scalable Controls for Gas & Electric Machines

Industry: Process engineering / grain micronization

Location: UK build & worldwide deployments

Services: Controls design, PLC/HMI software, commissioning, remote support

Technology: Siemens S7‑1500F & S7-1200F family, ET200SP & ET200AL I/O, WinCC Unified, Profinet/Profisafe, OPC UA

Executive Summary

More information to be found here: https://www.process-ir.co.uk/

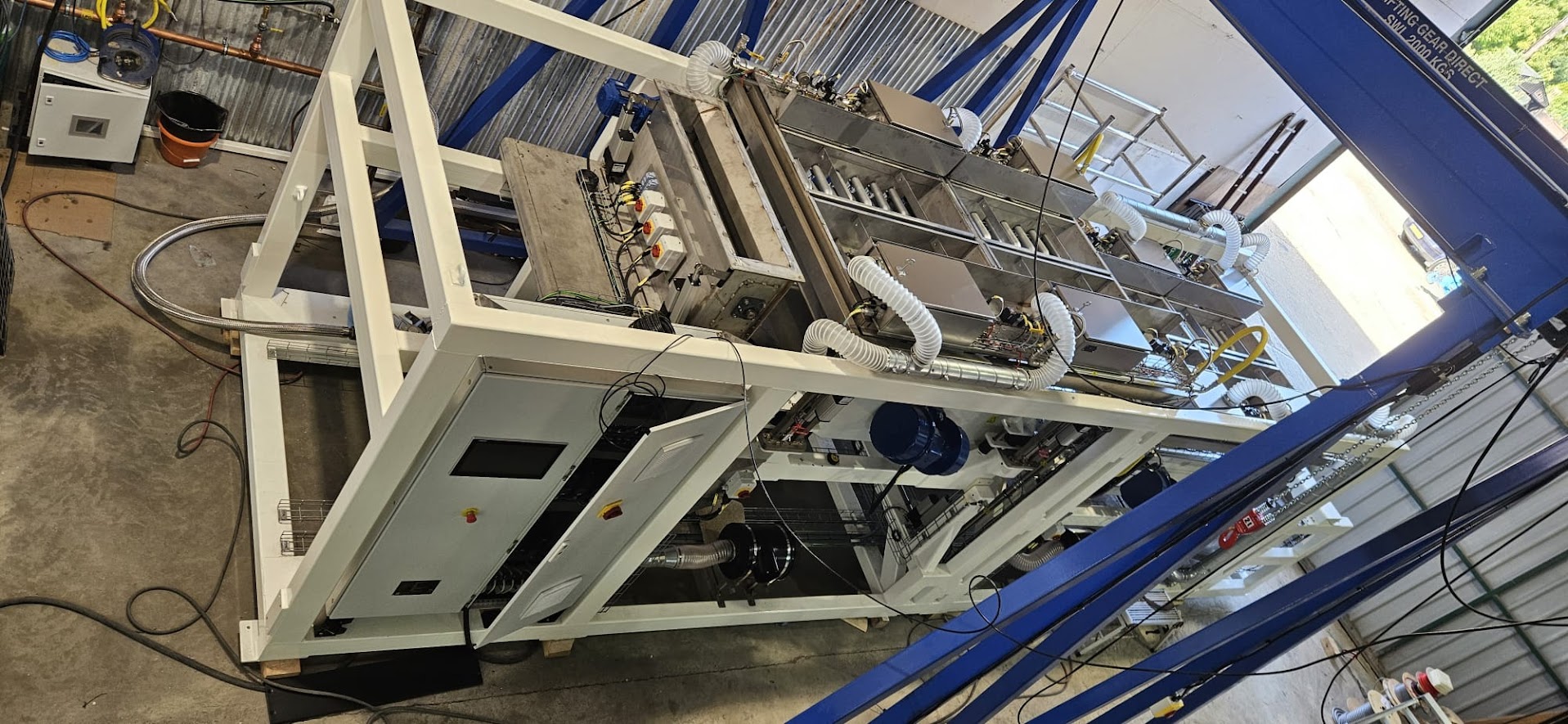

CDDC Engineering delivered a scalable control platform for a family of micronizer machines—from pilot‑scale units to high‑throughput production lines. The solution supports both gas‑fired and electric‑heated variants, standardises safety and operations across sizes, and introduces segmented control via external panels for modular expansion and straightforward maintenance. Customers now deploy the same core software and electrical philosophy across sites, reducing cost, training time, and downtime.

Outcomes at a glance

- Standardised control codebase across all sizes machines

- Gas & electric options built on a common safety and process template

- Segmented architecture: plug‑in external panels for feeders, classifiers, cooling, and utilities

- Recipe‑driven operation with audit trails and batch reporting

- Remote diagnostics and support

The Challenge

Micronizer OEMs and operators typically face three hurdles:

- Scale variance: Pilot units and full production machines need different IO counts and safety concepts yet should feel identical to operators.

- Energy choice: Supporting gas burners (with burner management) and electric heaters (with multi‑zone control) without forking the codebase.

- Maintainability: Rapid swap‑out of subsystems (feeders, fans, classifiers, dust collection) with minimal re‑engineering and clear fault diagnosis.

Our Solution

CDDC Engineering designed a Siemens‑based platform that is modular by design:

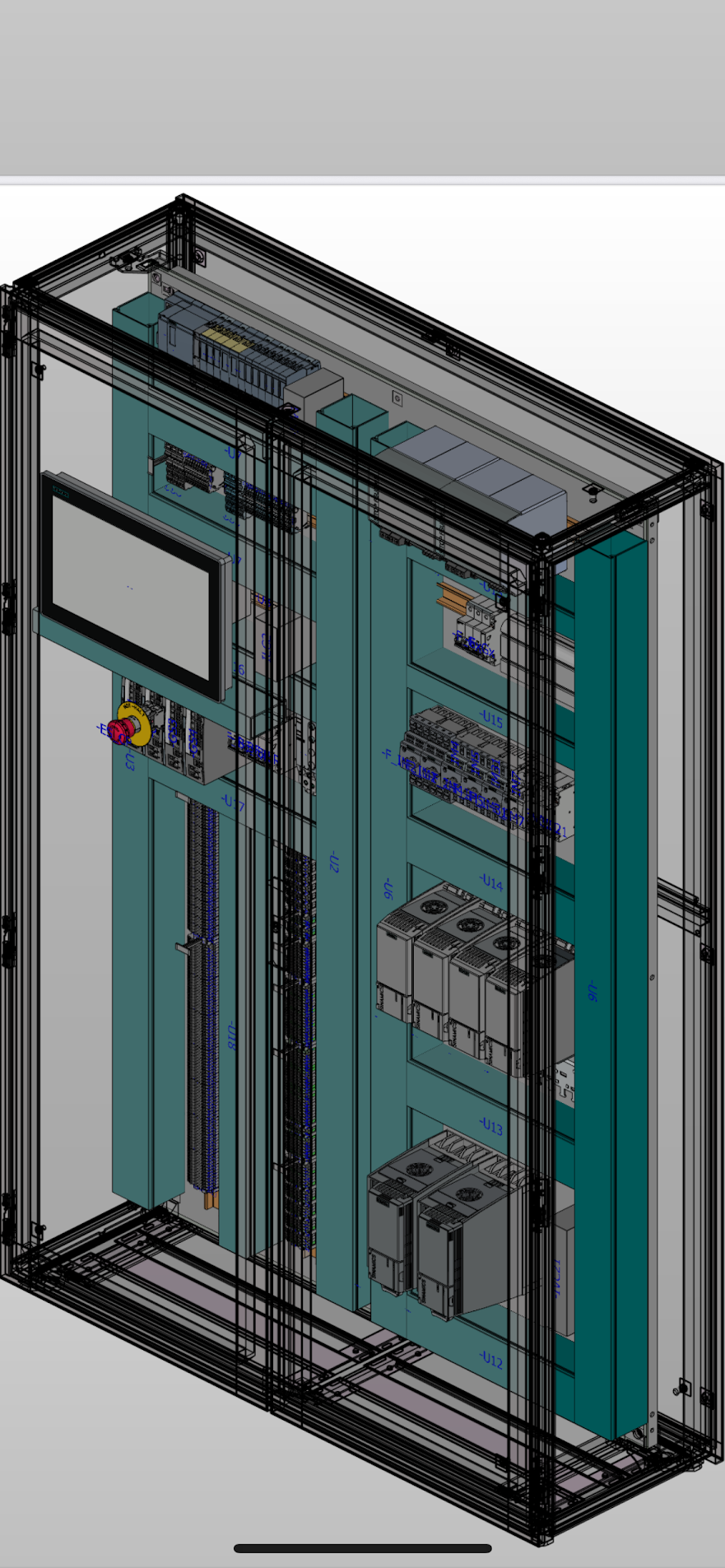

Core PLC & HMI

- PLC: Siemens S7‑1500F or S7-1200F

- Remote I/O: ET200SP & ET200AL for compact footprints and flexible channel mixes

- HMI: WinCC Unified; consistent screens from 10" operator panels up to 21" line terminals

- Networking: Profinet for I/O and drives; Other available for data exchange with plant systems

Segmented Control with External Panels

- Each process segment is housed in its own external local panel.

- Segment controllers expose clear status, interlocks, and isolation points for safe maintenance.

Gas & Electric Heating Templates

- Gas option: Integrated burner management philosophy with permissives, flame supervision, and staged control.

- Electric option: Multi‑zone heater control with soft‑start, current monitoring, and thermal profiling.

- Both variants share common logic based on recipes, alarms, trending, and interlocks, so operators experience a consistent interface.

Safety & Compliance

- Architecture prepared for functional safety using fail‑safe I/O where gas firing is present.

- Clear interlock matrix and Cause‑&‑Effect (C&E) documentation provided.

- Electrical design aligned with applicable UK/EU/UL/cUL standards and customer specifications.

Data, Recipes & Reporting

- Recipe management for setpoints and PID tunings per product grade.

- Batch reporting with time‑stamped events, parameter snapshots, and alarms.

- Trending & diagnostics views for pressure, temperature, airflow, and vibration.

Remote Support & Expandability

- Secure remote access option for diagnostics, firmware updates, and operator support.

- New segments (e.g., additional classification stage or cooling loop) can be added with minimal software change—I/O and faceplates follow a library pattern.

Results

- Reduced engineering time: Common library blocks and faceplates cut new variant delivery time.

- Faster commissioning: Segment self‑tests and guided permissive checks reduce start‑up issues.

- Lower downtime: Clear diagnostics and segment isolation simplify troubleshooting.

- Operator consistency: Identical HMI structure across machine sizes and energy options.

- Future‑proofing: Easy to scale throughput by adding or upgrading segments.

Project Scope (Typical)

- Process & instrumentation diagrams (P&IDs)

- Electrical design & panel build

- PLC/HMI software (libraries, faceplates, recipes)

- Site installation support & commissioning

- Operator training & documentation

- Ongoing remote support and enhancements

Notes & Options

- Available with multilingual HMI packs.

- Can integrate energy meters and condition‑monitoring sensors.

- Interface options for plant historians/MES via OPC UA or file drop.